featured products

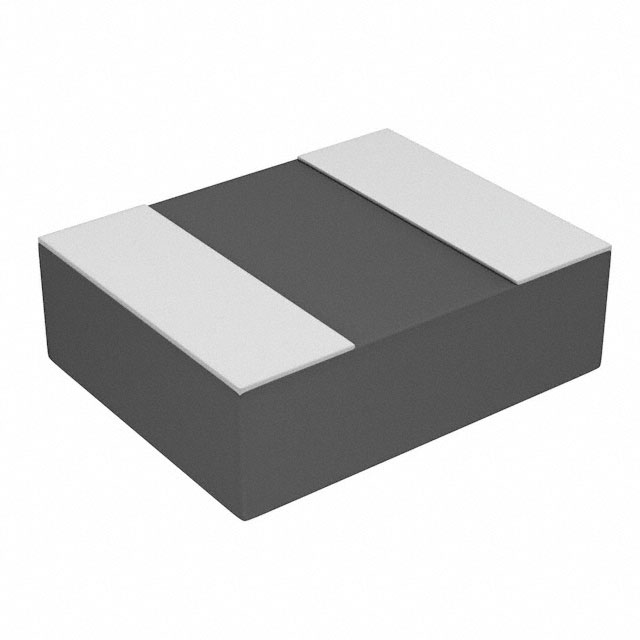

Würth Elektronik Midcom

FIXED IND 1UH 1.75A 133 MOHM SMD

$1.51

3956 available

Würth Elektronik Midcom

FIXED IND 1UH 1.25A 196 MOHM SMD

$1.51

4596 available

Würth Elektronik Midcom

FIXED IND 470UH 900MA 490MOHM SM

$2.52

1600 available

Würth Elektronik Midcom

FIXED IND 47UH 3.2A 67 MOHM SMD

$2.52

2150 available

Würth Elektronik Midcom

FIXED IND 220UH 1.45A 245MOHM SM

$2.52

1600 available

Würth Elektronik Midcom

FIXED IND 22UH 4.3A 44 MOHM SMD

$2.52

2317 available

Würth Elektronik Midcom

FIXED IND 1MH 630MA 1.06 OHM SMD

$2.52

1600 available

Würth Elektronik Midcom

FIXED IND 100UH 2.2A 120MOHM SMD

$2.52

3285 available

Würth Elektronik Midcom

FIXED IND 10UH 5A 30 MOHM SMD

$2.52

2015 available

Würth Elektronik Midcom

FIXED IND 6.8UH 5.5A 24 MOHM SMD

$2.52

1600 available

Würth Elektronik Midcom

FIXED IND 4.7UH 6A 19 MOHM SMD

$2.52

1600 available

Würth Elektronik Midcom

FIXED IND 3.3UH 7A 17 MOHM SMD

$2.52

1600 available

78438322010

78438321010

7847709471

7847709470

7847709221

7847709220

7847709102

7847709101

7847709100

7847709068

7847709047

7847709033

7847709022

7847709010

784778471

784778470

784778221

784778220

784778101

784778100

784778082

784778068

784778047

784778033

784778022

784778010

784777471

784777470

784777221

784777220

784777102

784777101

784777100

784777082

784777068

784777047

784777033

784777022

784777010

784776247

784776239

784776233

784776227

784776222

784776218

784776215

784776212

784776182