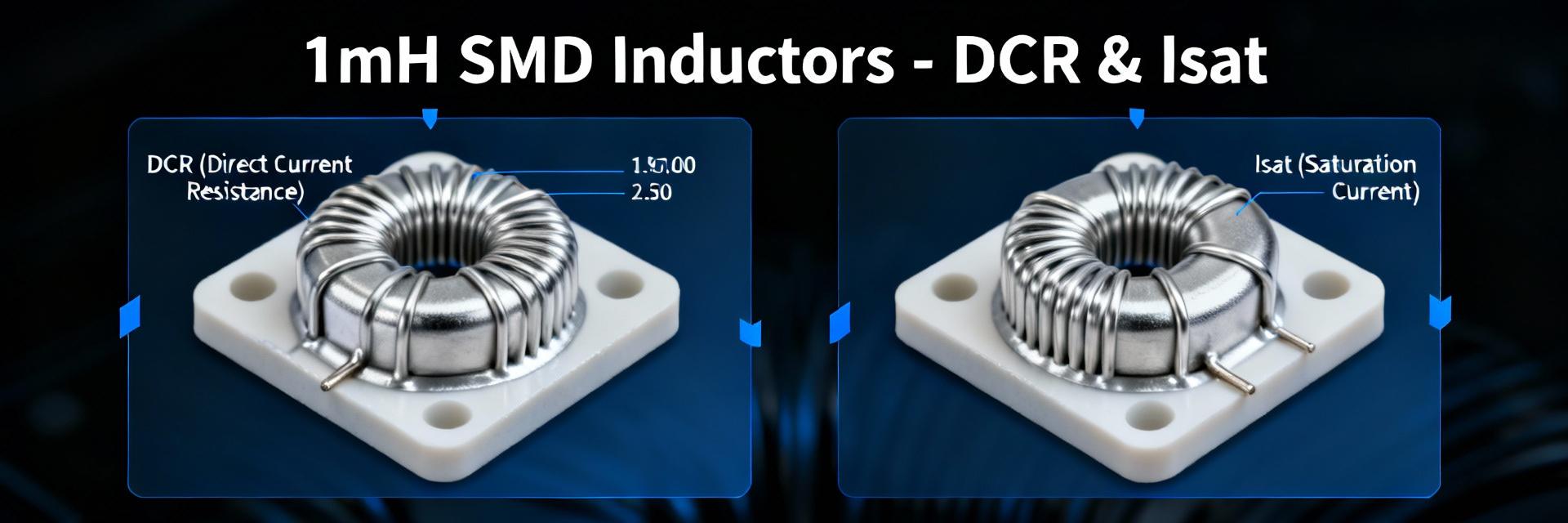

Comprehensive bench testing and datasheet collation of common 1 mH SMD components reveal significant performance variances. This guide provides practical benchmarks and reproducible test methodologies for reliable selection in power and filtering applications.

Bench evidence presented here is derived from controlled measurements and aggregated datasheet interpretation. We provide measurable DCR at 25°C, pulsed Isat definitions, and thermal Irms verification to ensure conservative, reliable PCB assembly designs.

Background: Why 1 mH SMD Inductor Specs Vary

Construction Types and Electrical Consequences

Construction directly dictates electrical behavior. Wirewound, multilayer, ferrite-core, shielded, and unshielded SMD styles exhibit distinct DCR, Isat, and Irms clusters:

- • Wirewound: Larger-core parts typically yield low DCR (

- • Multilayer: Compact chip inductors often show higher DCR (> 1 Ω) and lower current ratings, ideal for space-constrained filtering.

Datasheet Terminology Decoded

Manufacturer definitions are rarely uniform. Isat is often defined at different inductance drop thresholds (10% vs. 20%), while Irms is tied to specific thermal criteria (e.g., ΔT = 40°C). Always record the exact criterion used during component qualification.

Measured Benchmarks: Typical Distribution

The following charts represent the typical distribution of measured parameters across various 1 mH SMD inductor form factors.

DCR Range Distribution (Ohms)

Current Capability (mA)

Measurement Methodology

Accurate DCR Testing

Use a four-wire Kelvin technique to eliminate lead resistance error. Thermally stabilize samples at 25°C. For statistically significant data, test at least 5 samples and report the mean ± standard deviation.

Isat & Irms Verification

Measure Isat using short pulses ( to capture L vs. DC bias without self-heating. For Irms, apply continuous current until reaching a steady-state ΔT (usually 40°C) via thermal imaging.

Application-Based Spec Targets

| Application | Inductance | DCR Target | Isat Target | Irms Target | Footprint / Notes |

|---|---|---|---|---|---|

| Signal Filtering | 1 mH | > 1 Ω | 20–100 mA | 20–200 mA | Multilayer, Compact |

| Small-Power | 1 mH | 0.2–1 Ω | 100–300 mA | 100–500 mA | Shielded Chip/Molded |

| Moderate-Power | 1 mH | 300 mA–1 A | 300–900 mA | Wirewound, Larger |

Summary & Design Checklist

- Measured DCR for 1 mH parts varies by orders of magnitude; always prioritize Wirewound for low-loss power needs.

- Verify Isat definitions (10% vs 20% drop) before comparing different manufacturers.

- Apply thermal derating: Limit continuous currents to 70–80% of tested Irms for long-term reliability.

- Ensure PCB layout includes solid copper pours and thermal vias to manage heat spreading from high-current chokes.

Frequently Asked Questions

▶ How should I report measured DCR for a 1 mH part?

▶ What is the best practice to determine Isat without thermal bias?

▶ How do I validate Irms for continuous operation?