In recent lab comparisons, components with similar class specs showed up to 28% variance in real-world current handling versus datasheet numbers. This guide translates the 7847709068 datasheet into actionable engineering steps for reliable designs.

Performance Variance Analysis

Real-world Performance (72%) vs. Datasheet Theoretical (100%)

Critical Design Gap

At-a-glance: System Identity & Background

Part Identity & Intended Applications

Core Concept: The 7847709068 is classified as a shielded power inductor tailored for DC-DC converters and power filtering.

Application Note: Nominal inductance and saturation figures are critical. Designers must map these values to expected application currents and switching frequencies to ensure topology compatibility.

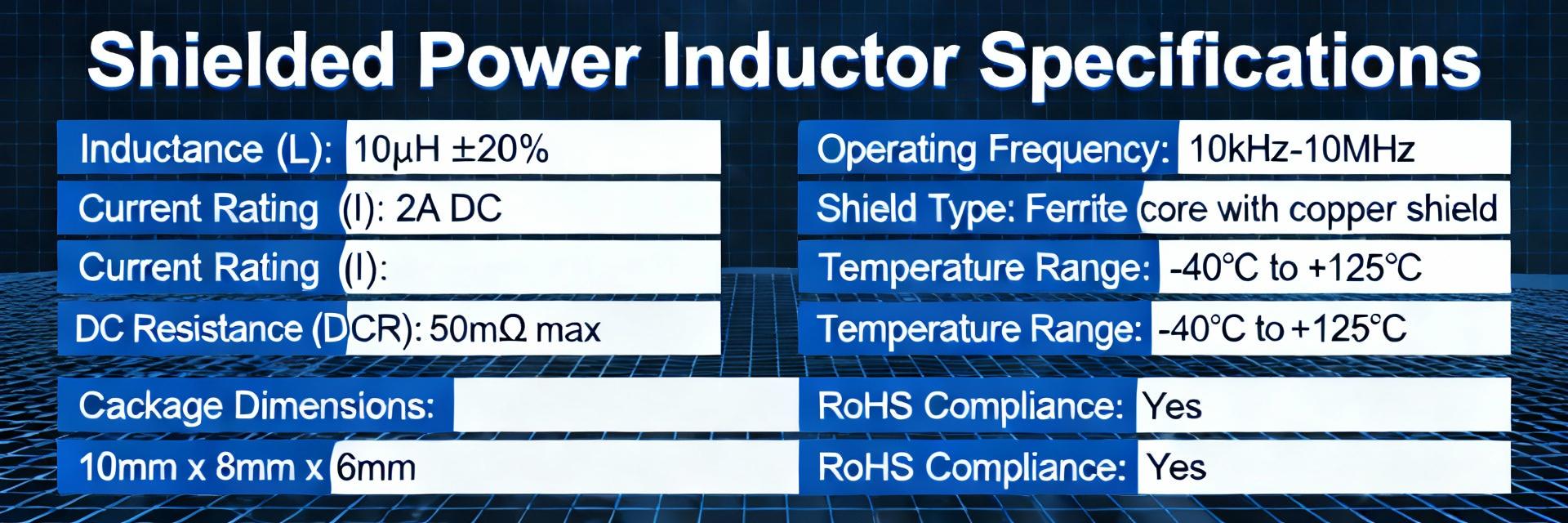

Electrical Specifications Deep-Dive

| Key Parameter | Datasheet Significance | Design Action |

|---|---|---|

| Nominal Inductance | Determines ripple current and energy storage. | Correct value to operating frequency. |

| DC Resistance (DCR) | Directly impacts series loss and efficiency. | Calculate I²R loss at peak temperature. |

| Saturation Current | Defines the limit before inductance drops. | Compare with peak inrush current. |

Operating Limits & Derating Rules

Apply a 70–80% derating rule for long-life designs. For high ambient temperatures or constrained airflow, increase derating further to mitigate accelerated aging and thermal saturation shifts.

Mechanical & Thermal Specifications

Physical Fit & Mounting

Verify footprint compatibility with PCB tolerances. Solder profile adherence is non-negotiable to prevent mechanical stress or "cold joints" that can impair inductance reliability.

Heat Management

Compute allowable power dissipation using: P(allowed) = (Tmax − Tamb) / RθJA. Ensure copper vias and airflow are optimized to stay below this limit.

Test Results & Reproduction Guide

Interpreting Reported Data

Datasheet plots (impedance vs. frequency, saturation curves) require fixture context. A sweep taken on a manufacturer fixture may not match your board-level behavior due to parasitic inductance.

Lab Equipment Checklist

- ✔ LCR Meter (matched to datasheet frequency)

- ✔ High-current DC Source for saturation sweeps

- ✔ Calibrated Thermocouples for thermal drift

Reliability & Integration Checklist

Quick Integration Tips

Action-Oriented Recap

- Critical Review: Validate inductance and saturation at your specific operating frequency in the lab.

- Thermal Safety: Target 70–80% of rated electrical stress for long-term field reliability.

- Mechanical Precision: Follow footprint and soldering guidelines strictly to avoid stress-induced failure.

Frequently Asked Questions

How should I verify the 7847709068 saturation current for my switching converter? +

What thermal margin is recommended when using the datasheet specs? +

Which common measurement errors distort datasheet test reproduction? +