Recent bench testing shows that measured inductance under DC bias and actual RDC values frequently determine real-world converter behavior more than nominal datasheet numbers. In practice, a power inductor that meets a catalog L at zero-bias can still underperform once biased and heated on-board. This report explains how to measure inductance and RDC, typical deviations, and practical actions for designers and buyers.

Why Measured Inductance and RDC Matter

Electrical Role in Power Converters

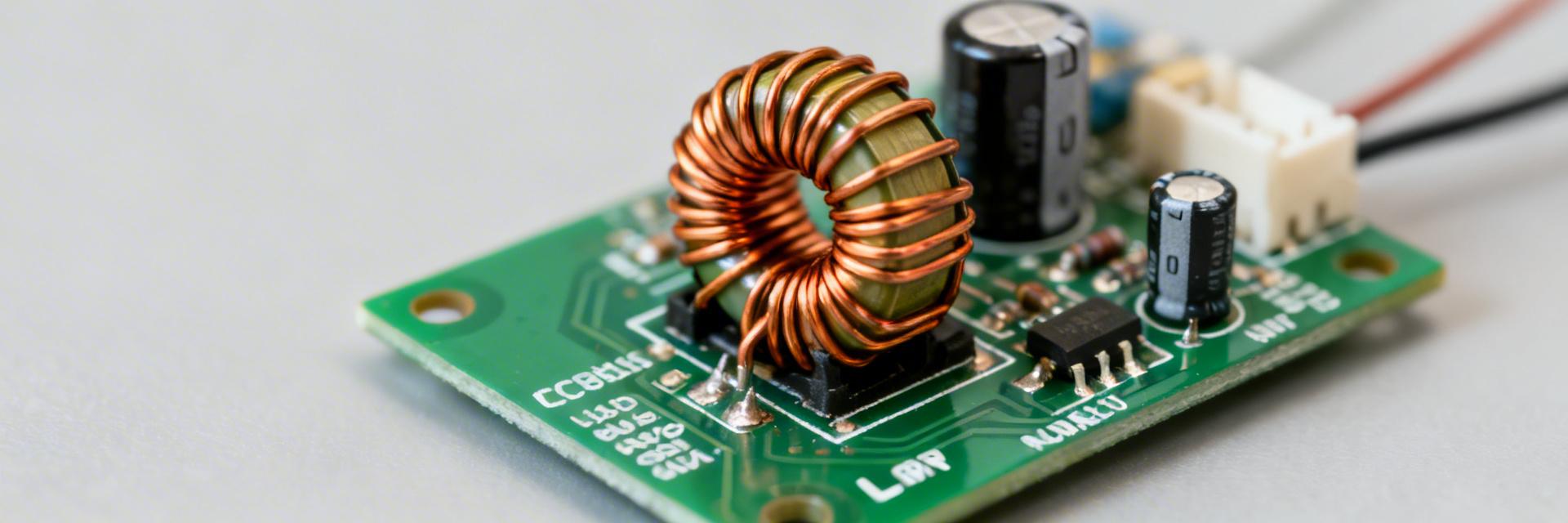

Inductance and RDC set ripple magnitude, transient energy, peak currents, EMI, and copper losses. Ripple current ΔI relates inversely to L and switching frequency; I²R defines copper loss.

ΔI = (Vsw · D) / (L · fsw)

Pcu = I_RMS² · RDC

Datasheet Definitions & Test Conditions

Datasheets report inductance and RDC under specific test conditions (e.g., 25°C, specific frequency) that may not match system use. Missing DC-bias curves or unspecified fixture details cause discrepancies between lab values and real-world performance.

* Recommendation: Always request L vs. DC-bias curves and fixture descriptions from suppliers.

Data Patterns: Typical Measured Value Trends

Inductance: Frequency and DC-Bias

Core materials respond differently to bias. Ferrite cores often show pronounced L reduction under bias, while powdered cores tend to be more linear.

RDC: Variation with Temperature

Copper's temperature coefficient (~0.4%/°C) raises RDC with heat. At high frequencies, skin and proximity effects increase effective resistance beyond DC RDC.

A 50°C rise in temperature results in a ~20% increase in RDC. Designers must budget for realistic on-board resistance rather than catalog nominals.

How to Measure Inductance and RDC Properly

Required Equipment & Fixturing

- • LCR Meter: Covering low kHz to switching frequencies.

- • Kelvin Source-Meter: For precise RDC measurement (4-wire).

- • DC Bias Source: External current source for saturation testing.

Step-by-Step Procedure

- 1 Precondition parts and perform Short/Open compensation.

- 2 Measure L at baseline and actual switching frequency.

- 3 Apply bias points (0%, 25%, 50%, 75%, 100% of Isat).

Example Measured Report and Interpretation

| Bias Current (A) | Nominal L (µH) | Measured L (µH) | Deviation (%) | Measured RDC (mΩ) |

|---|---|---|---|---|

| 0.0 (Baseline) | 10.0 | 9.85 | -1.5% | 12.4 |

| 5.0 (50% Isat) | 10.0 | 8.92 | -10.8% | 12.5 |

| 10.0 (100% Isat) | 10.0 | 6.40 | -36.0% | 12.7 |

* Highlighted cells flag parts needing further review or larger design margins.

Supplier Specification Template

- Inductance at specified DC bias points.

- RDC at 25°C via 4-wire Kelvin method.

- Acceptance: ±10% L, ±15% RDC.

- Required L vs. Bias curve data.

Design Rules & Derating

- Assume 20-30% less L than nominal.

- Include measured RDC in copper-loss calcs.

- 20-50% saturation headroom for transients.

- Thermal vias under pads for heat dissipation.

Summary

- Reality Check: Measured inductance under DC bias and measured RDC determine converter ripple, losses, and thermal behavior. Don't rely solely on datasheet nominals.

- Best Practices: Use LCR or impedance analyzers for sweeps and Kelvin micro-ohm methods for RDC. Apply standardized DC bias points.

- Action: Budget for reduced L (20–30% margin), include real RDC in I²R loss budgets, and require explicit vendor curves.

Frequently Asked Questions

What is the best way to measure inductance under DC bias? +

How should RDC measurement be specified for procurement? +

How do measured deviations affect thermal estimates? +