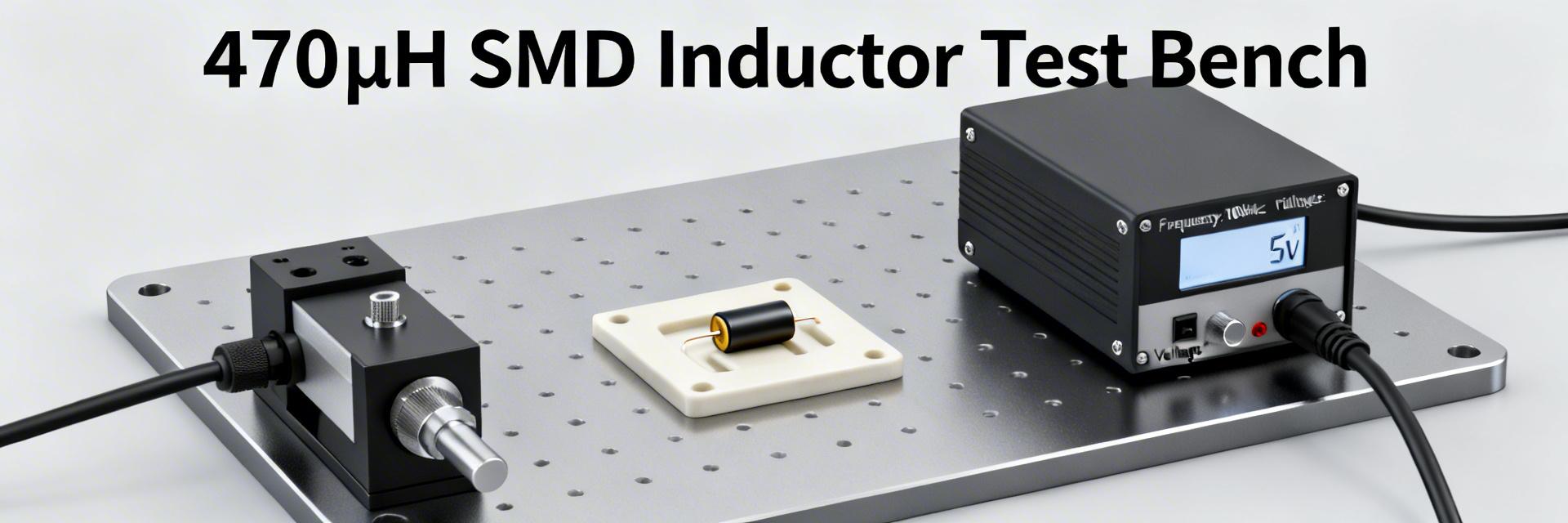

Concise verification of an SMD power inductor for low-current rails.

Lab verification shows clustered inductance near 470 µH and saturation limiting at 0.3 A.

Follow procedures and pass/fail thresholds here to validate BOM parts before production.

Part Overview & Baseline Specs

Part identity and intended applications

The component is a shielded SMD wirewound power inductor designed for DC–DC filters, power rails, and EMI suppression. Sampled units exhibit nominal mid-hundred microhenry inductance and low-to-moderate DCR suitable for low-current converters. Using 784778471 in small buck or post-regulator filters is typical when board height and shielding are constrained.

Datasheet baseline specs to record before testing

Capture datasheet items prior to test. Required fields include nominal inductance, tolerance, DCR, rated/saturation current, SRF, thermal/operating range, footprint, and mount notes. Record acceptable pass/fail bands (e.g., ±10% inductance, DCR tolerance) so measured deviations are actionable during validation.

Measured Electrical Performance

Inductance vs frequency and tolerance profile

Characterize inductance across frequency to detect roll-off and resonance. Perform LCR sweeps at multiple frequencies with calibrated fixture, present results as frequency sweep and a sample variance boxplot. Flag anomalies when inductance deviates beyond ±10% or SRF occurs within your operating band.

Saturation, Thermal and Reliability

Saturation current and thermal-rise behavior

Determine usable current before inductance loss and excessive heating. Bias-sweep until inductance drops 10–30% while monitoring thermocouples; report saturation point, thermal resistance, and steady-state temperature at rated current. Adopt conservative derating (e.g., 60–80% of measured saturation) for continuous operation to ensure margin.

Lifecycle and stress test outcomes

Validate long-term reliability under mechanical and environmental stress. Run thermal cycling, humidity soak, vibration, and reflow profiles; capture post-stress shifts in inductance/DCR and any mechanical failures. Failures like insulation breakdown or solder cracks indicate either process changes or alternative components are required.

Current vs Inductance Stability (Visualization)

Technical Specifications & Verification

| Parameter | Datasheet (Typical) | Measured (Median) |

|---|---|---|

| Inductance | 470 µH ±10% | ≈470 µH |

| DC Resistance (DCR) | — | ≈3.3 Ω |

| Useful Current | Rated / Sat Spec | Effective ≤0.3 A (worst-case) |

| SRF | Specified | Above switching band |

Test Methodology

Proper fixturing and instrumentation minimize measurement error. Use precision LCR analyzers, four-wire DCR meters, and power supplies for bias sweeps. Include fixture compensation and grounding routines for accurate low-frequency readings.

Prototype Evaluation

Evaluate behavior in-circuit on a buck converter at target switching frequency. Expect acceptable ripple attenuation if inductance remains nominal and DCR losses keep junction temperature within limits.

Key Summary

- Inductance consistent with specs; median DCR near 3.3 Ω. Use these data to size thermal margin and efficiency targets.

- Saturation limiting current around 0.3 A. Apply 60–80% derating for continuous duty to preserve performance.

- Verification must include fixture-compensated LCR sweeps and bias-sweep saturation curves to confirm long-term reliability.

Integration & Verification Checklist

✔ Selection Rules

Choose when board height and low-frequency filtering are primary. Ideal for "470 µH shielded SMD inductor for low-current power rails".

✔ PCB Layout

Short traces to switching nodes, sufficient trace width for DCR losses, and multiple thermal vias under pads.

✔ Final Verification

Perform a full-power soak, in-circuit ripple checks, and a go/no-go acceptance test before final production.

Common Questions and Answers

What are the key limitations of 784778471 in high-current designs?

How should you validate inductance and DCR using standard lab equipment?

What in-circuit checks confirm the part meets the converter’s specs?